THE TEK MECHANICAL CASSAVA HARVESTER(TEK-MCH)

DEVELOPED @KNUST FOR THE WORLD

THE CHALLENGES

The low level of engineering technology inputs into agriculture is one main constraint hindering the modernization of agriculture and food production in many parts of the developing world.

Cassava (Manihot esculenta Crantz) is an important food security, industrial and energy crop in the world. Its roots provide dietary carbohydrates for over 800 million people. Global cassava production in 2012 was 282 million tonnes, with 56% in Africa, 30% in Asia, and 14% produced in South America.

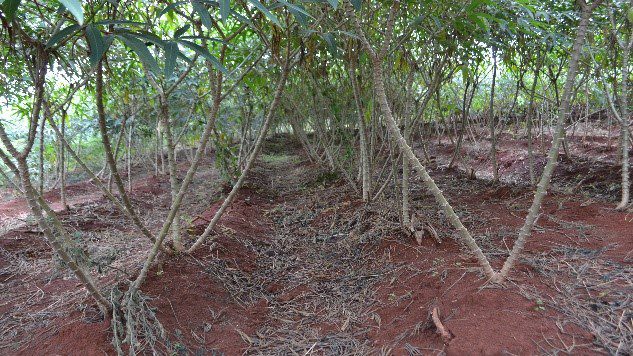

Harvesting is a major constraint to commercializing cassava production in sub-Saharan Africa. Manual cassava harvesting is a painful, stressful and time-consuming activity full of drudgery especially, during the dry season.

Until recently, there are no commercial mechanical cassava harvesters in use by cassava growers in Africa. This makes cassava production to be full of drudgery, unattractive to the youth and dependent on ageing farmers, who produce limited outputs with little export potential.

Slow and painful manual cassava harvesting

THE OPPORTUNITY

Efficient TEK Mechanical Cassava Harvester in operation

The development and use of a device to harvest cassava mechanically are one solution proposed to unlock the huge potential of cassava as an industrial and export crop.

A prototype mechanical cassava harvester of 300 kg mass and one metre wide with a slatted conical mouldboard has been developed at KNUST and evaluated in Ghana and South Africa for large-scale cassava production.

Cassava as a climate-smart and resilient crop provides excellent insurance against famine for farmers. Cassava is a bio-fuel source that can replace fossil fuels.

To create awareness about the harvester innovation, field demonstrations, and training of farmers and tractor operators to adopt best practices to comply with mechanized operations must be stepped up.

This is to introduce and popularize the harvester to farmers, tractor owners, scientists, entrepreneurs, donors, policymakers and other stakeholders in the cassava value chain on the continent.

The harvester has no moving parts and is robust, durable and easy to maintain. The only replaceable part is the digging blade that wears after harvesting several hectares.